Whether it’s a natural gas plant or another, the extraction of natural resources has always been challenging because of the presence of highly flammable gasses, such as methane, ammonia, acetylene, etc. In these regions, even a light spark can be very dangerous, so work must be done by following the utmost safety standards, including the use of a Flame Proof Electric Wire Rope Hoist.

The spark-proof electric wire hoist is quite popular in plants rich in flammable gasses because it gives the best output without producing any spark. The mechanical components of this device are coated with a blend of phosphorus-bronze to prevent any explosion in the plant.

The Globe’s Spark Proof Electric Wire Rope Hoist is the best in the standard as each element of this utility is perfectly designed and meets all the safety norms.

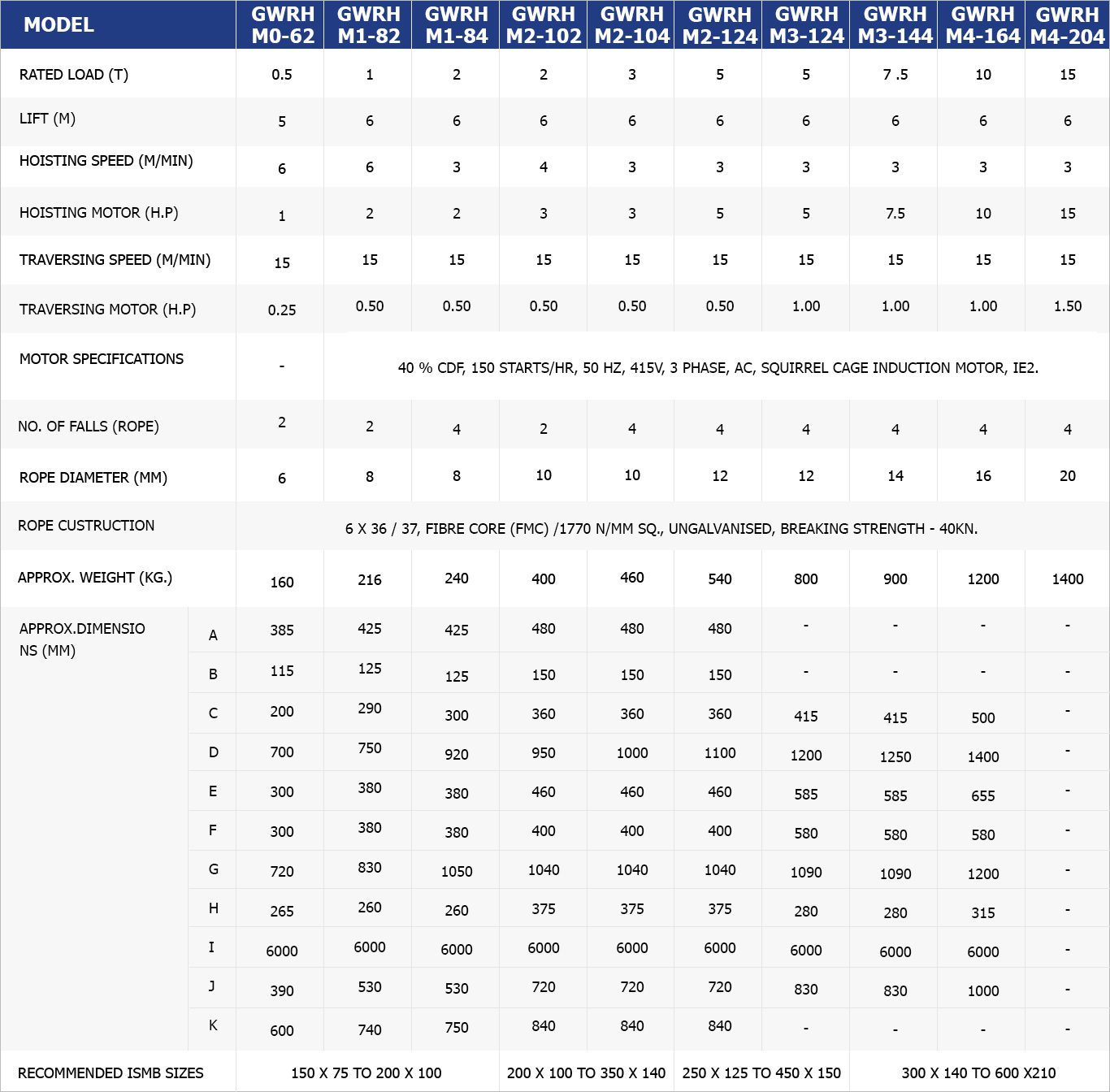

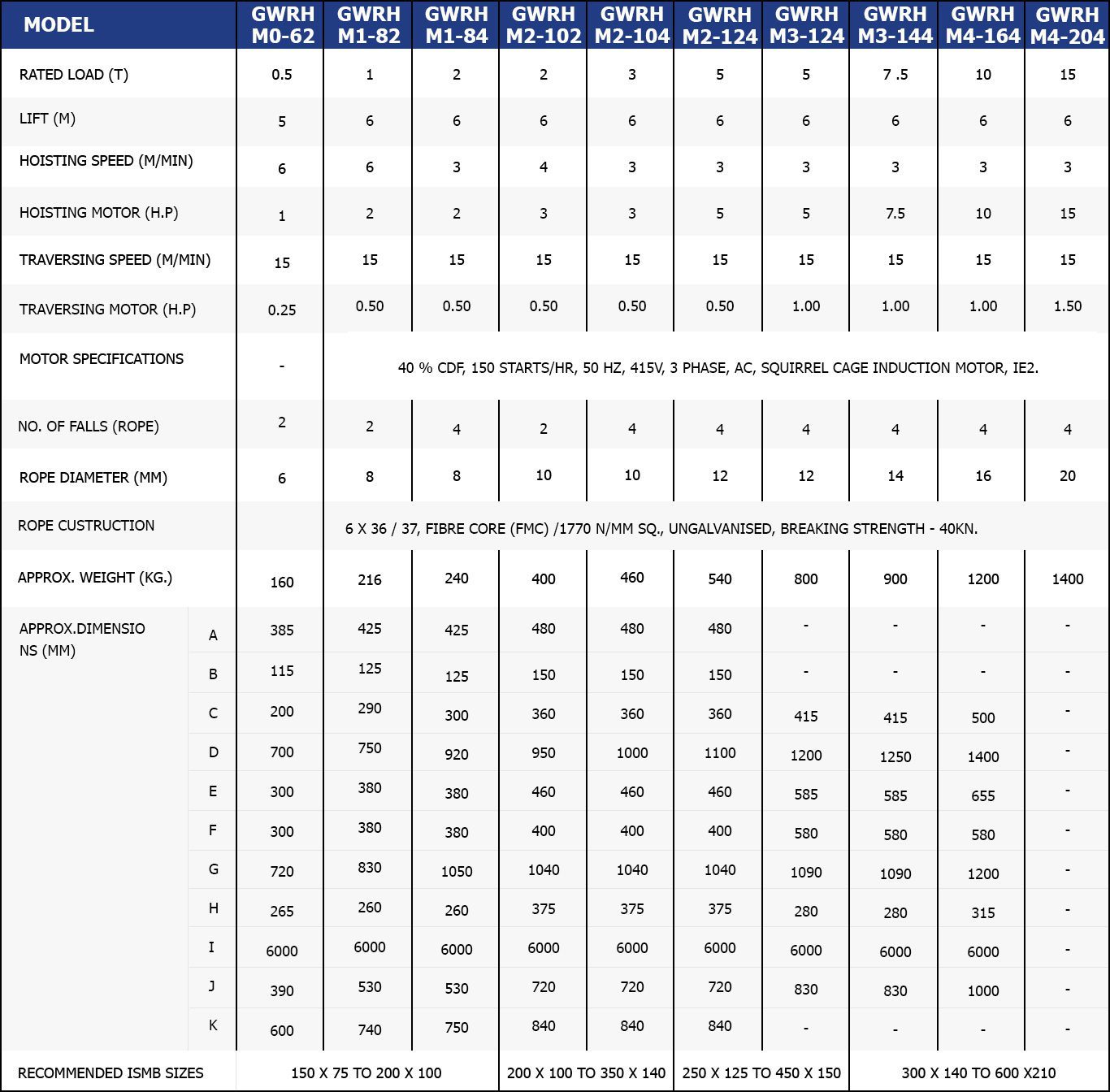

In addition, such a device can lift heavy objects from 1 ton to 15 tons, which is applicable for single girders. To lift the objects beyond the specified limit, you can go with double girders where the Globe’s Flame Proof Wire Hoist can lift above 15 tons to 25 tons weight.

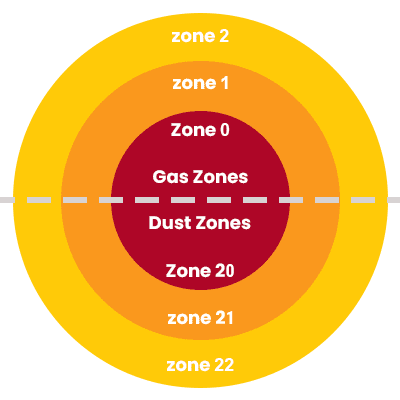

The work is performed with high-class safety standards in a hazardous area where flammable gasses are abundant in nature. The reason is a light spark can explode an entire plant, and many people can get hurt. To prevent the same, all the equipment, whether mechanical or electrical, is designed that is suitable for those regions.

The Globe Flame Proof Electric Wire Rope Hoist is manufactured as per the industrial norms that include;

Electrical Components

The main component of a flameproof electric wire rope hoist is the induction motor that transfers electrical energy to mechanical energy to the rotating device. The motor used in the Globe’s flameproof wire rope hoist and other components, such as the Brake, Limit Switch, and Push Button, is ATEX Certified.

Mechanical Components

The mechanical components of a spark-proof electric wire rope hoist need phosphorus-bronze coating. The reason is that friction between the metals can cause a spark, which can be dangerous for such a plant.

So, to avoid any kind of friction, a coating is applied. The mechanical components in Globe’s Spark Proof Electric Wire Rope Hoist are perfectly coated with phosphorous-bronze. In addition, the materials used in this device are non-ferrous such as Brass or Gun Metal.

Key Areas Where Globe Spark Proof Electric Wire Rope Hoist Can Be Used

Globe Flame Proof Electric Hoist is specially designed for use in hazardous areas, and a list of a few is provided below.

1] Coal Mines

2] Refineries

3] Chemical Process Plants

4] Gas Power Plants

5] Warehouse