Electric Wire Rope Hoist (With Electric Travelling Trolley)

₹83,072.00 – ₹237,153.00 incl. GST

Safe & Reliable

Electric Wire Rope Hoists are designed, manufactured & tested to meet IS standards, Robust Gearbox design ensures better reliability of the product life span and safety.

More Details:

- HSN Code: 84251110

- Warranty: 12Month

- 100% Original Products

- Secure Payments

- 100% Buyer Protection

Description

Can Meet Various Demands Of The Customer

We as a leading electric wire rope hoist manufacturer serve electric wire rope hoist to our customers with various models and designs to meet their ultimate demands.

High Quality Ensures Good Working Performance

All components manufactured are passed through several quality checks, which helps us to ensure the improved working performance of the equipment.

Wire Rope & Rope Guide Arrangement

High tensile 1960 N/MM Sq. wire rope with good flexibility is used with the precisely machined Guiding arrangement which increases the life of the electric wire rope hoist and is served very safely.

Heavy-Duty Mechanical Parts

The complete structure of the electric wire rope hoist is heavy-duty designed which provides rigidity to the machine for smooth and better operation.

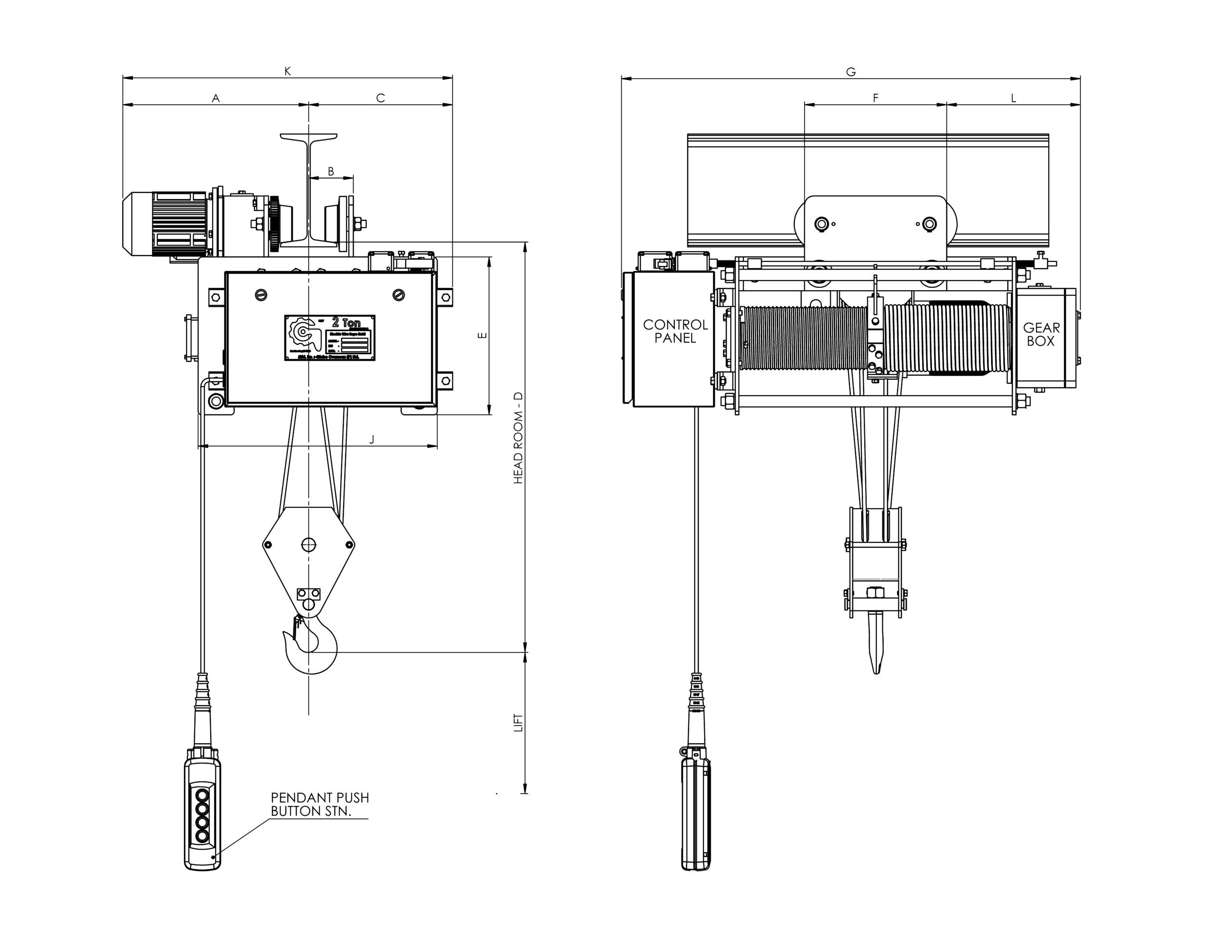

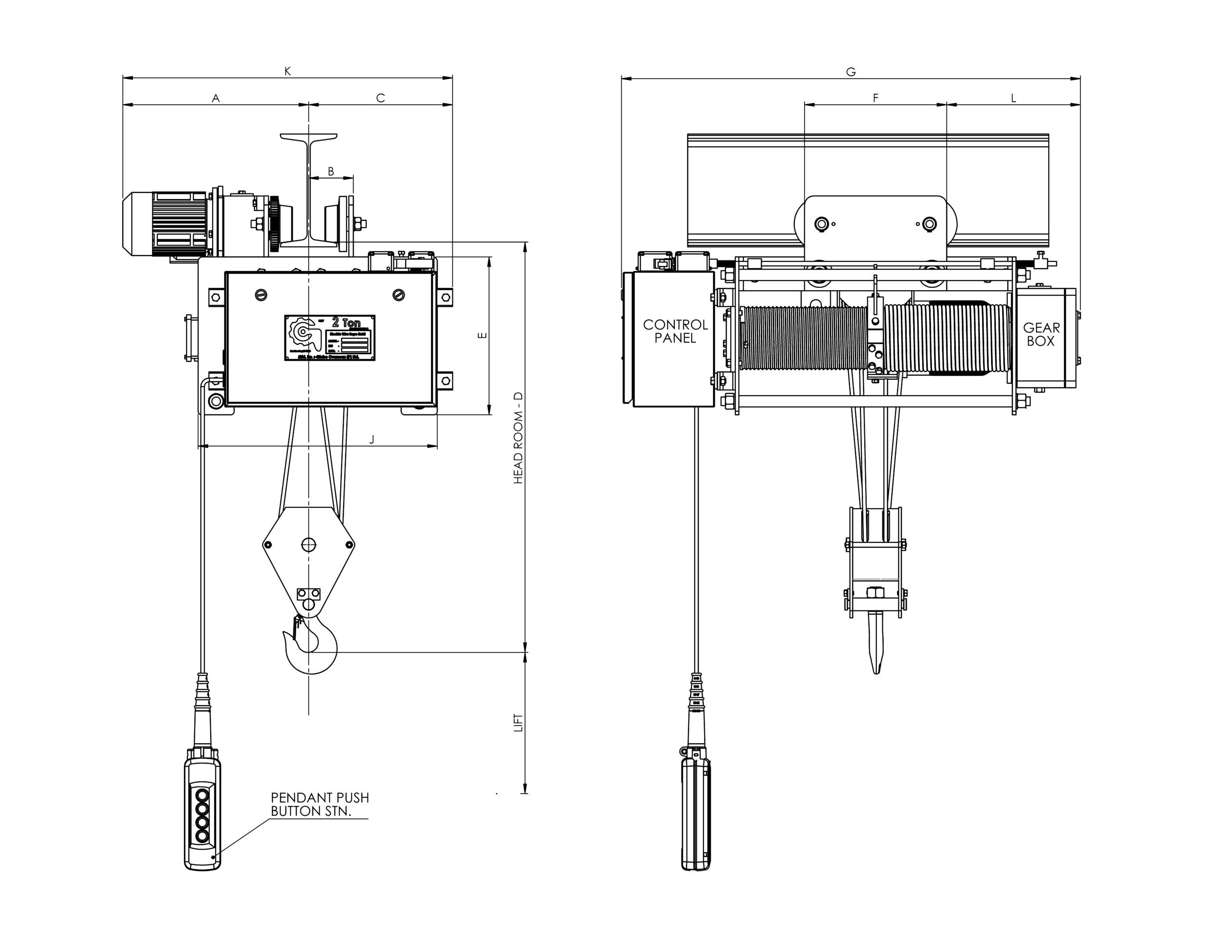

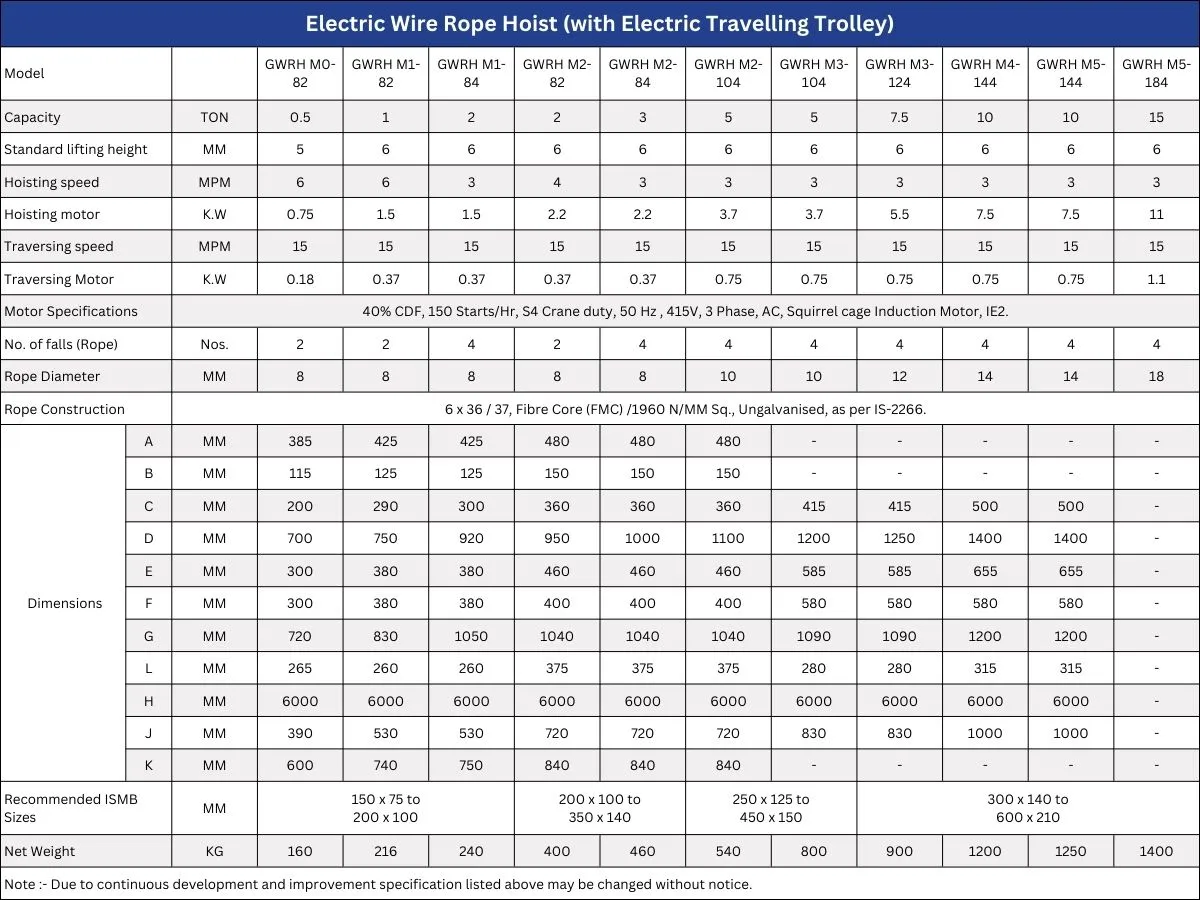

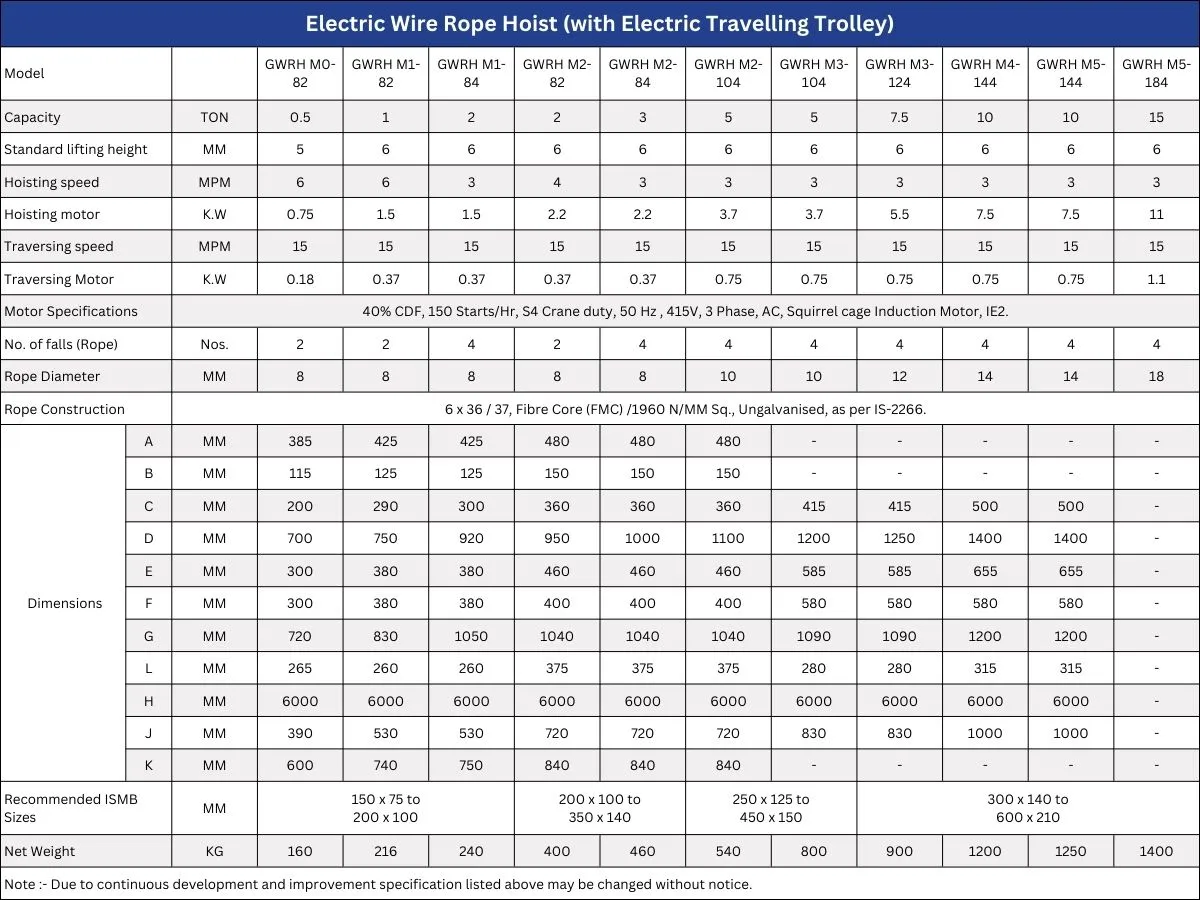

Electric Wire Rope Hoist Item Description:

Heavy-duty fabricated Structure for hoisting & trolley, Cast iron Gear Box Housings with High Precision-cut Oil Cooled Helical internal gears & Pinion makes this machine the most demanding Machine in the industry. All Standard models of Electric wire rope hoists are designed with M5 & M6 rated Gearboxes to improve machine performance.

Heavy Duty ball & Spherical Roller Bearings are provided for Gear Box and Wire rope Drums. Capacity ranging from 0.5 Ton-15 Tons for Single girders are available in different models.

Application:

Electric Wire Rope Hoists are the most preferred Lifting equipment in almost all types of Industry.

- Assembly Shops

- Cement Industries.

- Glass Industries

- Steel Industry

- Textile Industry

- Heavy Fabrication Workshops.

- Coil Handling

Features / Advantages:

- Fail-safe Electro Magnetic – Instant braking Arrangement.(DC)

- Heavy-duty Electric Motors.

- Provided with safety limit switches.

- Increase Productivity.

- Micro Operating speeds by V3F Control Panels.

- Unbreakable and high-performance push button pendent stations.

- Customization can be done with Operating speeds and electrical Protection.

- Flame Proof Hoists are also available for all variants.

- Can be provided with Higher lifts

Electric Wire Rope Hoist Variants:

- Hoist with Manual Trolley – Electric Hoists are provided with Manual Geared or Push-pull Trolley for Load Movement in Monorail beam. Hoisting Motion will be electrical and cross-travel motion would be manual.

- Hoist with Electrical Trolley – Electric Hoists are provided with an Electrical Trolley where hoisting and cross travel can be operated electrically through a push-button pendant.

Why Choose Globe Overseas?

“Globe” we are not only electric hoist manufacturers but also your partners for providing the best material handling solutions as per requirement. We provide a wide variety of lifting equipment.

We are Specialists in Design, Engineering, manufacturing, supply, installation, and after-sales service where we understand our customer’s requirements.

Salient Features

Technical Specifications

Flame Proof / Electric Hoist

Whether it’s a natural gas plant or another, the extraction of natural resources has always been challenging because of the presence of highly flammable gasses, such as methane, ammonia, acetylene, etc. In these regions, even a light spark can be very dangerous, so work must be done by following the utmost safety standards, including the use of a Flame Proof Electric Wire Rope Hoist.

The spark proof electric wire rope hoist is quite popular in plants rich in flammable gasses because they give the best output without producing any spark. The mechanical components of this device are coated with a blend of phosphorus-bronze to prevent any explosion in the plant.

The Globe’s Flame Proof Electric Wire Hoist is the best in the standard as each element of this utility is perfectly designed and meets all the safety norms.

In addition, such a device can lift heavy objects from 1 ton to 15 tons, which is applicable for single girders. And to lift the objects beyond the specified limit, you can go with double girders where the Globe’s Flame Proof Wire Hoist can lift above 15 tons to 25 tons weight.

Safety Standards Of Globe Flame Proof Electric Wire Rope Hoist

The work is performed with high-class safety standards in a hazardous area where flammable gasses are abundant in nature. The reason is a light spark can explode an entire plant, and many people can get hurt. To prevent the same, all the equipment, whether mechanical or electrical, is designed that is suitable for those regions.

The Globe Flame Proof Electric Wire Rope Hoist is manufactured as per the industrial norms that include;

Electrical Components

The main component of a flameproof electric wire rope hoist is the induction motor that transfers electrical energy to mechanical energy to the rotating device. The motor used in the Globe’s flameproof wire rope hoist and other components, such as the Brake, Limit Switch, and Push Button, is ATEX Certified.

Mechanical Components

The mechanical components of a spark-proof electric wire rope hoist need phosphorus-bronze coating. The reason is that friction between the metals can cause a spark, which can be dangerous for such a plant.

So, to avoid any kind of friction, a coating is applied. The mechanical components in Globe’s Spark Proof Electric Wire Rope Hoist are perfectly coated with phosphorous-bronze. In addition, the materials used in this device are non-ferrous such as Brass or Gun Metal.

Key Areas Where Globe Spark Proof Electric Wire Rope Hoist Can Be Used

Globe Flame Proof Electric Hoist is specially designed for use in hazardous areas, and a list of a few is provided below.

1] Coal Mines

2] Refineries

3] Chemical Process Plants

4] Gas Power Plants

5] Warehouse

Classification

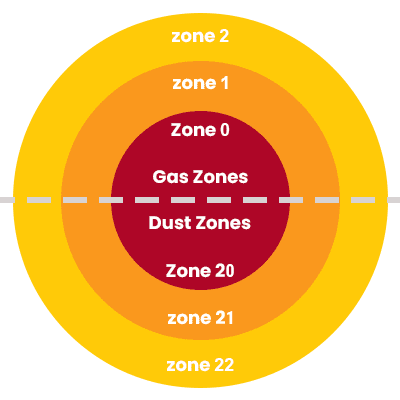

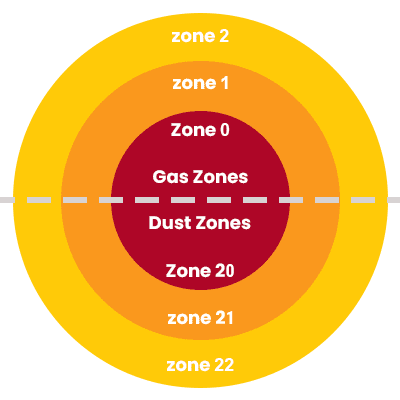

“GLOBE” Flame Proof Electric Hoists are offered for both Single Girder & Double Girder Mountings designed as per Hazardous Area Zone 1, Gas group IIA, Zone 2, Gas group IIA, IIB, IIC and Dust Zone 21 & 22 as per IS/IEC 60079-7.

Capacity Range :-

Globe Flame Proof Hoist are manufactured in wide range of lifting capacities for 1Ton to 15Ton in Single Girder & upto 25Tons for Double Girder.

Application Area’s

- Chemical process plants

- Coal mines

- Refineries

- Gas power plants

- Warehouse

Safety Features

- Electrical components like Motor, Brake, Limit switch, Push button pendent are ATEX certified.

- Mechanicals components like Hook are coated with phosphorus Bronze.

- All metal to metal contacts are designed and manufactured with Non – Ferrous material (Gun metal / Brass)

| Gas Zone | Definition |

|---|---|

| Methane | Mines with methane and dust. Equipment remains energised in explosive atmosphere |

| Methane | Mines with methane and dust. Equipment is de-energised in explosive atmosphere |

| Zone 0 | Explosive atmosphere present continuously or for long periods, frequently |

| Zone 1 | Explosive atmosphere is likely to occur under normal conditions, occasionally |

| Zone 2 | Explosive atmosphere is unlikely to occur under normal conditions, short period |

| Gas Groups | Definition |

|---|---|

| Gas Groups | Gases are classified according to the ignitability of the gas/air mixture as defined in EN/IEC 60079-20-1 |

| IIA | Acetic Acid, Acetone, Ammonia, Butane, Cyclohexane, Propane, Gasoline (petrol), Methane (natural gas, non-mining), Toluene, Xylene. Methanol (methyl alcohol), Propane-2-ol (iso-propyl alcohol) |

| IIB | Group IIA gases plus, Di-ethyl ether, Ethylene, Ethanol Methyl ethyl ketone (MEK), Propane-1-ol (n-propyl alcohol) |

| IIC | Group IIA and IIB gases plus, Acetylene, Hydrogen |

| Dust Zones | Definition |

|---|---|

| Zone 20 | Explosive atmosphere present continuously or for long periods, frequently |

| Zone 21 | Explosive atmosphere is likely to occur under normal conditions, occasionally |

| Zone 22 | Explosive atmosphere is unlikely to occur under normal conditions, short period |

Product Faq

Warranty is provided for the repair/ replacement of any part’s found defective in material or workmanship within 12 months from the date of supply (against any manufacturing defect).

Product has been tested on 25% overload.

Globe is ISO Certified Company.

Registered Office: B-9, DSIIDC Engineering Complex, Mangolpuri Industrial Area, Phase -1, New Delhi – 110083

Works 1: F-76, Sector – 2, DSIIDC Industrial Area, Bawana, New Delhi – 110039

Works 2: Khewat No. 646 Khasra No.178, BeriKultana Road, Sampla, Distt. Rohtak, Haryana – 124501

1. Paper industries 2. All Fabrication unit 3. Glass Industries 4. Automobile 5. Matters Industries 6.

Electrical Panel Manufacturing unit 7. Footwear 8. Textile Industries 9. Rolling Mills 10. Wire Drawing

units 11. Sheet Metal Industries 12. Plastic Molding units 13. Coil Handling 14. Transformer Industries

Similar Products

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Capacity (ton) | Cap. 0.5`Ton, Lift 6Mtr./M0, Cap. 1Ton, Lift 6Mtr./M1, Cap. 2Ton, Lift 6Mtr./M1, Cap. 2Ton, Lift 6Mtr./M2, Cap. 3Ton, Lift 6Mtr./M2, Cap. 5Ton, Lift 6Mtr./M2 |

Reviews

There are no reviews yet.