Sale

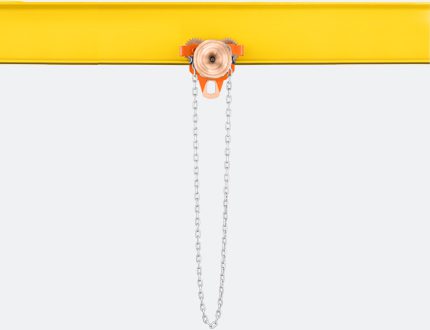

Flameproof Monorail Travelling Trolley

₹5,768.00 – ₹14,820.00 incl. GST

Description

Similar Products

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Capacity (ton) | 1Ton, Lift 3Mtr., 2Ton, Lift 3Mtr., 3Ton, Lift 3Mtr., 5Ton, Lift 3Mtr. |

Reviews

There are no reviews yet.