Monorail Travelling Trolley – Beam Trolley

₹6,433.00 – ₹17,900.00 incl. GST

Easy & Safe to operate – Design of the monorail travelling trolley provides minimum hand effort to operate on loaded capacities.

Derailing arrangements make our more safe & reliable.

Low maintenance – robust design reduces the maintenance cost after expiry of warranty.

Generates less noise – Precise Machining & heavy duty wheel bearings make the beam trolley sound less.

Adaptable in width so as to suit the I-Beam flange width demands.

Exchangeable Spares

More Details:

- HSN Code: 84251910

- Warranty: 12Month

- 100% Original Products

- Secure Payments

- 100% Buyer Protection

Description

Item Description of Beam Trolley:

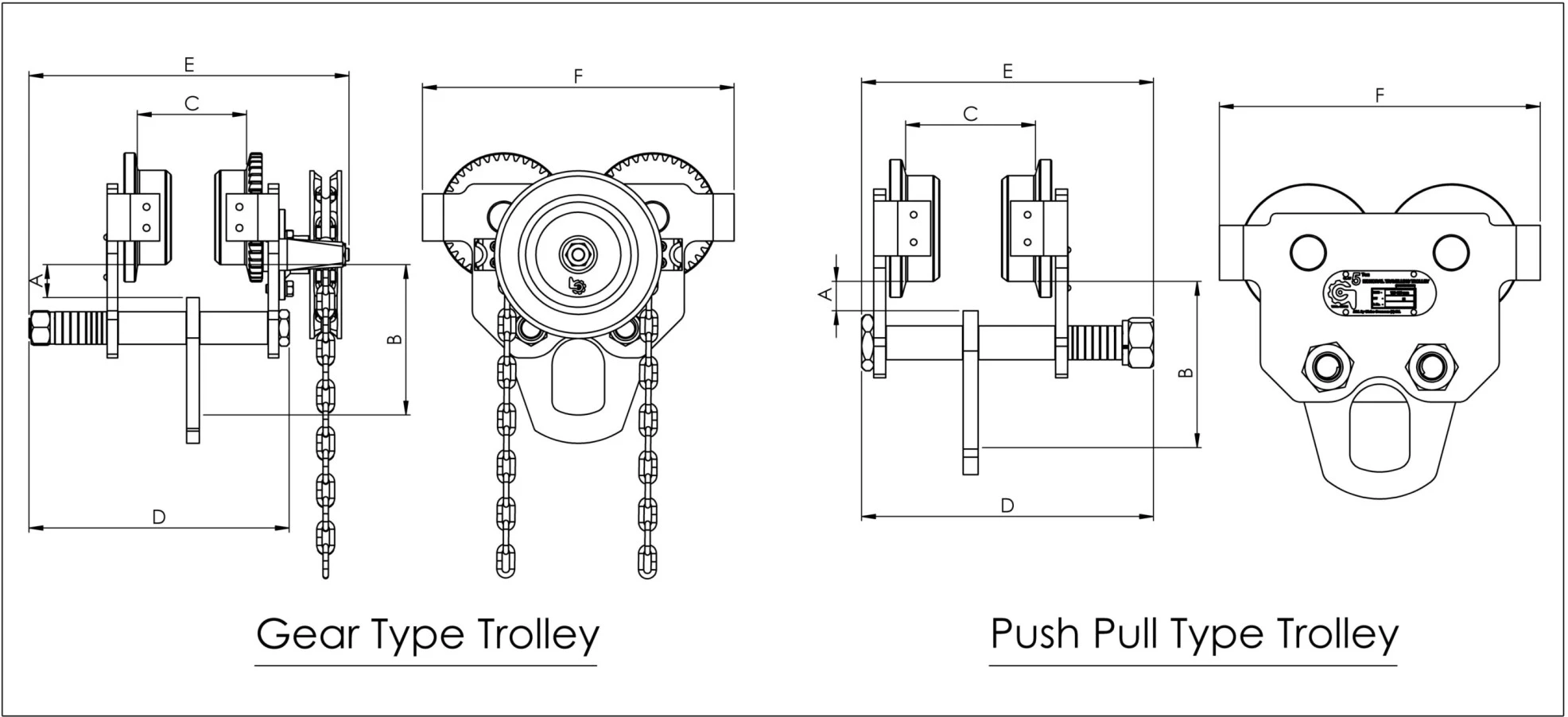

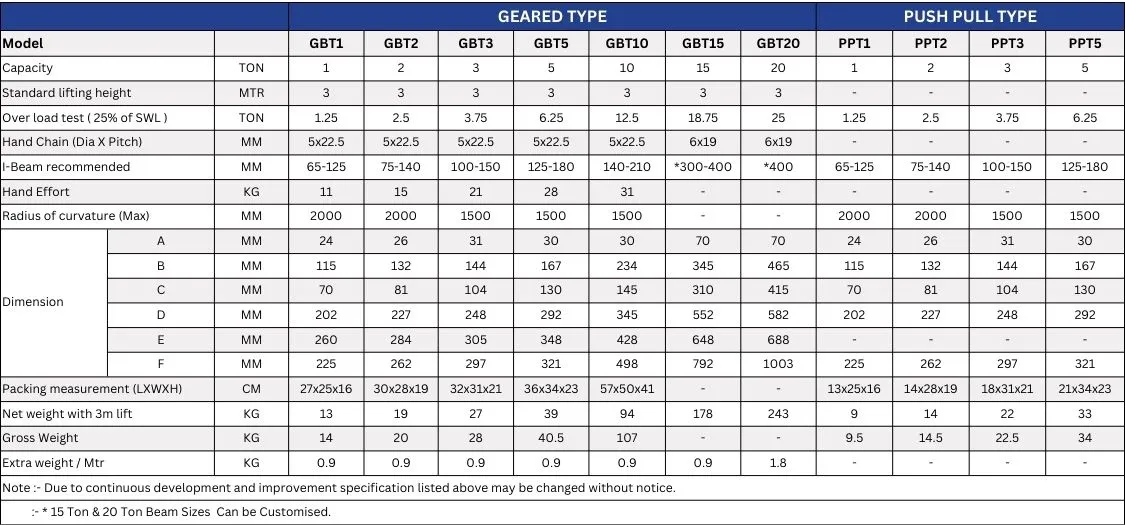

Monorail travelling trolleys are used with Manual Chain blocks & Electric Chain Hoists for the movement of goods on Monorail or Beam. Beam trolleys are available ranging from 1 Ton – 20 Tons. Trolleys are designed with adjustment of Variable sizes of the beam as per capacity. Beam Trolley wheels are mounted on Heavy-duty Ball bearings. It is available in 2 Variants.

1.Geared Monorail Trolley

2. Push Pull Trolley

Application of Monorail Travelling Trolley:

Monorail travelling trolleys is preferred equipment used for Load movement in large type of industries, Few examples are -:

- Manufacturing and Assembly Lines.

- Construction Sites.

- Automotive Industries

- Tool rooms & fabrication shops Plastic Moulding units

- Generator Maintenance Room

- Pump Houses

Advantages of Beam/Monorail Travelling Trolley:

- Low Headroom

- Heavy-duty high Graded Cast Iron Wheels

- Heavy-duty Frame Plates

- Minimum hand efforts for Operators

- Anti Corrosion Powder Coated Frame Plate & Mounting Plates and Zinc coated trolley wheels

- Easy Installation

- Suitable to travel on curve beams as per company design

- Increased Productivity – Monorail travelling trolley can significantly increse productivity by streamlining material handling processes.They provide a quicker and more efficient means of transporting heavy loads compared to manual labor, Reducing the time and effort required for material Movement.

- Enhanced Safety – Industrial monorail traveling trolleys are equipped with the safety features such as Anti-derailing. This feature help prevent accidents and injuries,ensuring the safety of both workers and the load being transported.

- Reduced manual labor and fatigue- The use of monorail traveling trolleys eliminates the need for manual lifting and carrying of heavy loads, Reducing the risk of worker fatigue and injuries related to repetitive lifting tasks. This leads to improved worker morale and decreased downtime due to potential injuries.

- Improved load control and stability – Monorail traveling trolleys operate on a track system, Providing smooth and controlled movement of the load. This Ensures Precise Transportation,Minimizing the risk of load shifting or damage during transportation.

Why Choose Globe Overseas?

- Quality & Reliability – Every product manufactured by the globe has been cleared by 3 stage inspection. Hence it is safe to use for safe working loads

- Make in India – All Products are designed, Manufactured tested in India

- Continuous Improvement – Our Development team work continuously to understand customer needs and implement the same with our Products.

- Superior Grade Material – All child parts are made with the best-in-class material recommended to achieve longer part life.

Technical Specifications Of Beam Trolley

Product Faq

Warranty is provided for the repair/ replacement of any part’s found defective in material or workmanship within 12 months from the date of supply (against any manufacturing defect).

Product has been tested on 25% overload.

Globe is ISO Certified Company.

Registered Office: B-9, DSIIDC Engineering Complex, Mangolpuri Industrial Area, Phase -1, New Delhi – 110083

Works 1: F-76, Sector – 2, DSIIDC Industrial Area, Bawana, New Delhi – 110039

Works 2: Khewat No. 646 Khasra No.178, BeriKultana Road, Sampla, Distt. Rohtak, Haryana – 124501

1. Paper industries 2. All Fabrication unit 3. Glass Industries 4. Automobile 5. Matters Industries 6.

Electrical Panel Manufacturing unit 7. Footwear 8. Textile Industries 9. Rolling Mills 10. Wire Drawing

units 11. Sheet Metal Industries 12. Plastic Molding units 13. Coil Handling 14. Transformer Industries

Similar Products

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Capacity (ton) | 1Ton, Lift 3Mtr., 2Ton, Lift 3Mtr., 3Ton, Lift 3Mtr., 5Ton, Lift 3Mtr., 1Ton, Lift 4.5Mtr., 2Ton, Lift 4.5Mtr., 3Ton, Lift 4.5Mtr., 5Ton, Lift 4.5Mtr., 1Ton, Lift 6Mtr., 2Ton, Lift 6Mtr., 3Ton, Lift 6Mtr., 5Ton, Lift 6Mtr. |

FSC India.

FSC India.

Reviews

There are no reviews yet.