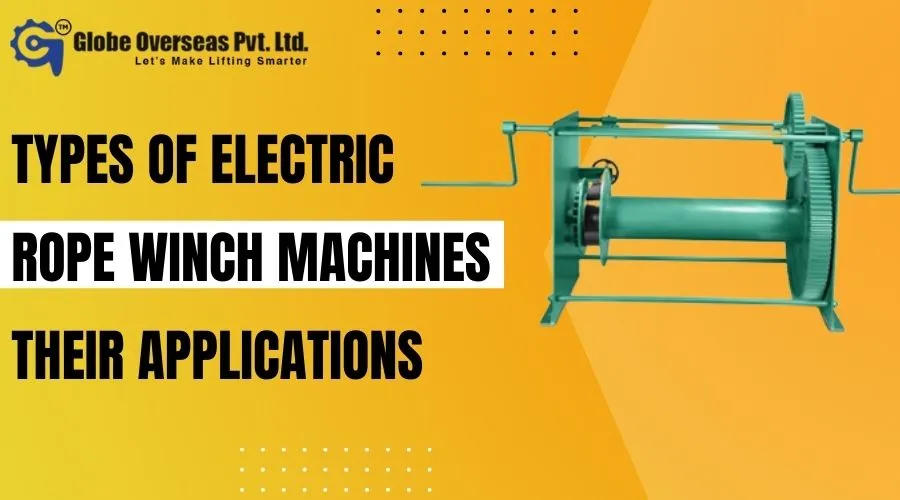

Electric winch machine is getting more popular in manufacturing and construction…

5 Warehouse Safety Tips – All you need to know!

Are you having a warehouse for industrial purposes? Do you have safety guidelines inside the warehouse? If not, read this blog, which helps you follow the warehouse safety tips? A warehouse owner must follow certain guidelines to ensure a safe method for employees. All you need to know about is safety. Because safety is the main thing to consider, warehouse owners must be involved in planning and give 100% safety to the warehouse.

You must follow these 5 warehouse safety tips without fail.

- Gives warehouse safety training

- Install warehouse safety signs

- Use of effective lighting

- Fire suppression systems

- Ventilate

1. Provide Warehouse Safety Training

Safety training is very important for the warehouse. It will give you no exception in handling everything safer. If there are any complicated and lengthy things inside, you have to find the training for the warehouse. You have to consider warehouse safety steps training including ergonomics training for the employees to handle everything safer.

2. Install Warehouse Safety Signs

Safety signs are very important in the warehouse. By seeing the safety signs, it ensures organized and hazardous situations. It will rely on the requirements and ensure racks, floors, equipment, and materials for preventing serious injuries. As a result, safety equipment reminders must give significant results to completely explore employees’ safety needs.

Related Articles

- Hand Pallet Truck: Ease of Warehousing and Manufacturing

- Mechanical Advantage & Efficiency of Double Reduction Crab Winch

- Difference Between Electric Winch Machine And Manual Winch Machine

3. Ensure the Use of Effective Lighting

Effective lighting gives a wonderful solution and explores changes in safety methods. A warehouse lighting improves safety for workers and protects their health. It will give you a wonderful solution to work without facing any risks. As a result, it offers maintenance that drastically minimizes the effects on the warehouse working atmosphere.

- Heavy-equipment accidents

- Losses and damages to property

- Dangers caused by poor stacking of products

- Forklifts striking people

4. Have Working Fire Suppression Systems

Fire suppression systems, on the other hand, include Warehouse Safety Steps. It will develop a good one and handle single protection to the entire warehouse. It takes multiple results and adapts to the high-end results for suppression systems. Depending on the protection, they ensure sprinkler requirements by focusing on the high result.

- Products are non-combustible and stored in pallets and single-layered

- Stored in wooden crates which are multi-layered

- Made from wood, natural fibres, paper, and group C plastics

- Group B plastics and partial needs

5.Ventilate

Finally, proper ventilation is required to give warehouse safety needs. Of course, it will give you a wonderful solution and explore air circulation forever. It ensures a good one and does carry out more outcomes.

Thus, it would help if you found the safety measurements to control and explore complete safety needs forever. Thus, you must get help from the Lifting Machines, which gives 100% safety guidelines for your warehouse.