Introduction Material handling plays a crucial role in industrial operations, ensuring…

A Comprehensive Guide to Beam Trolleys: Types, Uses, and Benefits

Beam trolleys are essential pieces of equipment for a range of industries, from construction and manufacturing to warehousing and logistics. Designed to move heavy loads along beams or monorails, these versatile tools can save time and increase efficiency in any workplace. However, with so many different types of beam trolleys available on the market, it can be difficult to know which one is right for your needs. In this comprehensive guide, we’ll take a closer look at the various types of beam trolleys, their uses and benefits, as well as important safety tips to keep in mind when using them. So whether you’re a seasoned professional or just starting out in your industry, read on to discover everything you need to know about beam trolleys!

What Is A Beam Trolley?

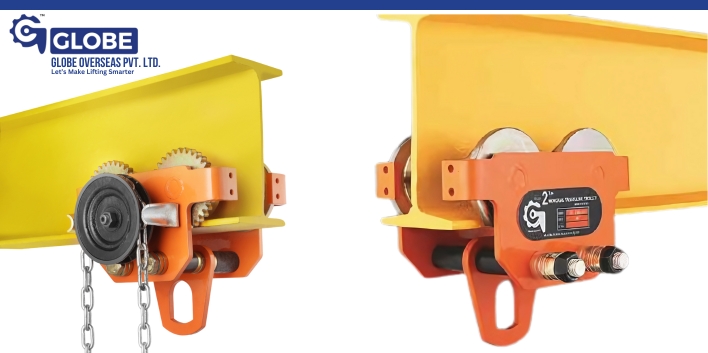

A beam trolley is a material handling device that is used to move heavy loads along an I-beam or monorail track. It consists of a frame, wheels, and a locking mechanism that secures it onto the beam. The wheels of the trolley allow it to travel smoothly along the length of the beam.

Beam trolleys come in various sizes and weight capacities, depending on their specific use. They can be manually operated or powered by electricity or air pressure.

One of the main advantages of using a beam trolley is its ability to transport heavy loads quickly and efficiently. By attaching lifting equipment such as hoists or chain pully blocks to the trolley’s hook attachment point, you can easily lift and move large items without having to rely on manual labor.

Beam trolleys are commonly used in industries such as construction, manufacturing, warehousing, and logistics. They can also be found in workshops and garages where they are used for vehicle maintenance tasks like moving engines and transmissions.

Beam trolleys are versatile tools that offer many benefits when it comes to transporting heavy loads safely and efficiently.

The Different Types Of Beam Trolleys

Beam trolleys come in different types, each designed for specific applications and weight capacity. One of the common types is the manual beam trolley, which allows for easy installation on an I-beam or monorail track. It features a simple hand chain to move the load along the beam manually.

Another type is the geared beam trolley that has a built-in gear system allowing it to travel along beams effortlessly, making them ideal for heavy loads. They are available in both manual and motorized designs depending on your needs.

For more specialized applications like curved tracks, adjustable flange widths and sloped beams, there are specialty beam trolleys designed to handle these unique requirements. These specialized trolleys ensure safety while transporting materials over uneven surfaces or around tight corners.

You can opt for electric-powered beam trolleys that offer smooth operation with minimal physical effort required from operators. They are perfect for high-frequency lifting operations where time efficiency is paramount.

Choosing the right type of beam trolley depends on your particular application requirements such as weight capacity and frequency of use. The good news is that there’s always a suitable option out there capable of meeting your demands!

The Benefits Of Using A Beam Trolley

Beam trolleys are an essential tool in various industries for a reason: they offer numerous benefits that make them indispensable to many businesses. Here are some of the key advantages of using a beam trolley:

Beam trolleys provide excellent mobility and flexibility. They can be easily moved along a track or rail system, allowing for easy transportation of heavy loads across long distances.

Using beam trolleys can significantly increase productivity and efficiency in the workplace. With the ability to quickly move items from one location to another, workers can complete tasks faster without having to waste time manually carrying materials.

Beam trolleys help reduce worker fatigue and injury risk. By taking on much of the load-bearing work, these devices greatly lessen the physical strain on employees while also reducing the likelihood of accidents caused by improper lifting techniques.

Investing in high-quality monorail traveling trolleys means companies save money over time as they don’t have to replace broken equipment frequently due to wear and tear caused by poor-quality products.

Utilizing beam trolleys has proven benefits that improve both workflow efficiencies and employee safety – making them an ideal addition for any business looking at improving their operations output with minimal investment costs.

How To Use A Beam Trolley?

Using a beam trolley is not as complicated as it may seem. However, to ensure safe and efficient use, there are certain steps that need to be followed.

Inspect the beam trolley before use. Check if all the components are in good condition and properly attached. Make sure that the load capacity of the trolley matches the weight of the load you intend to carry.

Next, attach the trolley to your hoist or lifting device using appropriate rigging methods. Make sure that all connections are secure and tightened properly.

Before lifting any loads, test run your beam trolley by moving it along a straight path without any obstructions or obstacles. This will help you identify any potential issues or problems beforehand.

Once satisfied with its functionality, move on to attaching your load securely onto the trolley’s hook or clamp mechanism. Ensure proper balance and centering of your load for smooth movement along tracks or beams.

Now you’re ready to lift! Use caution when operating your hoist system and monitor movement closely throughout the operation. Be aware of potential hazards such as overhead obstacles or uneven surfaces which can cause instability during transport.

Following these guidelines should result in the safe and efficient use of your beam trolley while reducing risks associated with improper usage practices.

Beam Trolley Safety Tips

When using a beam trolley, safety should always be the top priority. Here are some important tips to keep in mind when operating a beam trolley.

Make sure that the weight capacity of the beam trolley matches the weight of the load being carried and never overload it beyond its limit. Additionally, inspect the equipment before use to ensure there is no damage or wear on any parts.

When attaching your load to the trolley, make sure it is securely fastened and balanced evenly to prevent tipping or shifting during transport. Always move at a slow and steady pace while keeping an eye out for any obstacles or hazards on the path ahead.

It’s also essential to maintain clear communication with other workers in close proximity when moving loads with a crane system. Use hand signals or radios if necessary.

Ensure that you have received proper training before operating a beam trolley as well as wearing appropriate personal protective equipment like hard hats and steel-toed boots while working around heavy machinery.

By following these guidelines, you can reduce potential risks and ensure the safe operation of your monorail traveling trolley system.

Conclusion

To sum it up, beam trolleys are an essential tool in a variety of industries such as construction, manufacturing, and warehousing. They offer a safe and efficient way to transport heavy loads from one place to another.

With different types of beam trolleys available in the market today, choosing the right one for your specific needs is crucial. Consider factors such as load capacity, beam size compatibility, and ease of use when selecting which type of trolley is best suited for your application.

By following proper safety protocols when using a beam trolley, you can ensure that both operators and equipment remain unharmed during operation. Always remember to inspect your trolley before each use and never exceed its maximum weight capacity.

Investing in a quality beam trolley can greatly improve productivity and safety within your workplace. They provide an affordable solution for transporting heavy items across large distances while minimizing the risk of injury or damage to property. Choose wisely based on what works best for you!

Checkout Our Other Products: