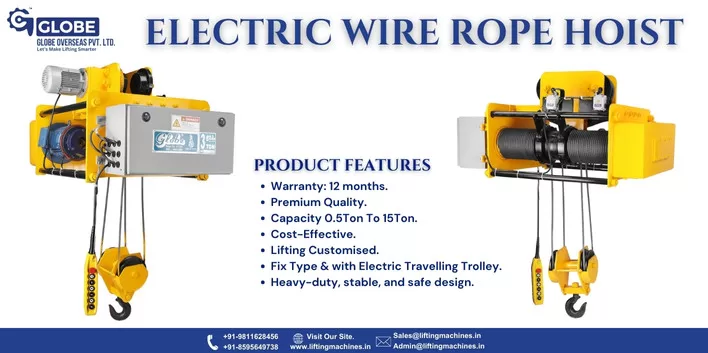

Introduction In the material handling industry, an Electric Wire Rope Hoist…

The Advantages of Using Electric Wire Rope Hoist in Material Handling

These innovative devices are revolutionizing material handling, offering a range of advantages that make them the go-to choice for businesses across industries. From increased safety and durability to enhanced productivity and cost-effectiveness, electric wire rope hoists deliver unparalleled performance in every setting.

Introduction to Electric Wire Rope Hoist

An electric wire rope hoist is a type of material handling equipment that uses an electrically powered wire rope to lift or lower heavy loads. Wire rope hoists are commonly used in industrial and construction applications and can be used to move materials of all shapes and sizes.

They are also more precise, allowing for greater control when lifting or lowering materials. In addition, wire rope hoists are much quieter than chain hoists, making them ideal for use in noise-sensitive environments.

Advantages in Material Handling

There are many advantages of using electric wire rope hoists in material handling applications. They are more efficient than manual hoists, they can be used in a variety of different settings, and they offer a number of safety features.

This can be used in a variety of different settings, including indoors and outdoors. They are also available in a variety of sizes to accommodate different load capacities.

A number of safety features include overload protection and emergency stop buttons. These features make them ideal for use in industrial settings where there is a risk of injury to workers.

– Efficiency

There are many advantages of using electric wire rope hoists in material handling applications. One of the most significant advantages is their efficiency. it offers a much higher degree of lifting power than manual chain hoists, allowing them to lift heavier loads with ease. Additionally, electric wire rope hoists can be precisely controlled, making them ideal for delicate or sensitive material handling tasks. Electric wire rope hoists also tend to be much faster than manual chain hoists, further increasing their efficiency.

– Safety

There are many advantages to using electric wire rope hoists in material handling, but safety is always the number one priority. Here are some of the ways that can help keep your workers safe:

1. eliminate the need for workers to manually lift heavy objects, which can reduce the risk of injuries.

2. can be equipped with safety features such as overload protection and emergency stop buttons, which can help prevent accidents.

3. They are generally easy to operate, so workers can be trained quickly and safely on how to use them.

4. regular maintenance and inspections of electric wire rope hoists can help identify potential safety hazards before they cause an accident.

– Cost-effectiveness

This is a cost-effective solution for material handling applications. They are designed for use in a variety of industries, including manufacturing, warehousing, and distribution. Electric wire rope hoists are available in a wide range of sizes and capacities to meet the needs of your application.

Wire rope hoists offer many advantages over other types of material handling equipment. They are durable and require little maintenance. They are also more efficient than hydraulic or pneumatic hoists, which can save you money on energy costs.

If you are looking for a cost-effective solution for your material handling needs, an electric wire rope hoist is an excellent choice.

Types of Electric Wire Rope Hoists

There are three main types of electric wire rope hoists: single-speed, two-speed, and variable-speed.

Single-speed wire rope hoists have a fixed lifting speed and are typically used for lighter loads. Two-speed wire rope hoists have two lifting speeds (low and high) and are great for heavier loads. Variable-speed wire rope hoists offer infinite control over lifting speed, making them ideal for delicate or sensitive loads.

Each type of chain hoist has its own advantages and disadvantages, so it’s important to choose the right one for your specific application. Single-speed hoists are less expensive than their two- and variable-speed counterparts, but they can only be used for lighter loads.

Two-speed hoists are more expensive than single-speed hoists, but they can handle heavier loads. Variable-speed hoists are the most expensive type of electric wire rope hoist, but they offer the greatest level of control and flexibility.

Maintenance and Operation Tips

A type of material handling equipment that uses an electric motor to lift and lower heavy loads. They are commonly used in industrial and commercial applications, such as factories, warehouses, and construction sites.

electric chain hoist have many advantages over other types of material handling equipment, such as chain hoists and hydraulic jacks. They are more efficient, easier to operate, and require less maintenance.

If you are considering using an electric wire rope hoist in your business, there are a few things you should know about maintenance and operation. Here are some tips:

1. Inspect the wire rope regularly for wear or damage. Replace the rope if necessary.

2. Check the pulleys and Sheaves for cracks or damage. Replace them if necessary.

3. Lubricate the moving parts of the hoist regularly with oil or grease. This will help extend the life of the equipment and prevent premature wear.

4. Always use proper lifting techniques when operating the hoist. Do not overload the equipment or exceed its rated capacity.

5. Store the hoist in a dry, clean area when not in use to prevent corrosion or damage from dirt and debris

Checkout Our Products: