Let’s face it — lifting heavy loads isn’t just part of…

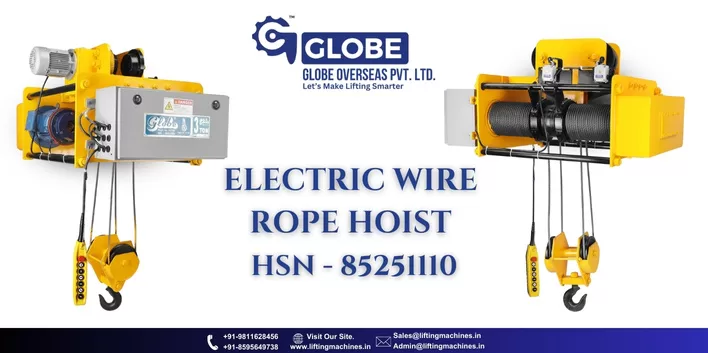

Durable & Reliable Electric Wire Rope Hoists for All Your Lifting Needs

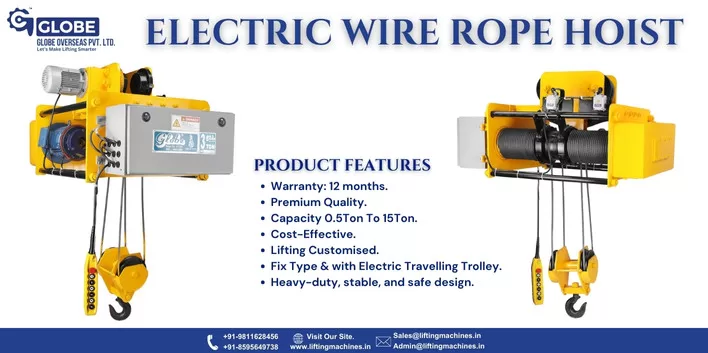

With today’s demanding manufacturing processes, it is imperative that manufacturers have access to the most reliable and efficient type of lifting equipment available. Lifting with electric wire rope hoists allows manufacturers to move heavy components and other materials efficiently without using manual muscle power. These types of hoists are reliable and durable. They are also economical to operate because they use minimal power and do not need oils or lubricants for operation. This article will explore everything you need to know about electric wire rope hoist types, maintenance, cost savings, installation, and more.

What is an Electric Wire Rope Hoist?

An electric wire rope hoist is a mechanical lifting device that uses two or more wires to transfer loads as well as to control the speed of the load. Most wire rope hoists are powered through an electrical wire. An electric wire rope hoist has a winch that winds the wire rope around pulleys, and the control system controls the speed of the hoist. An electric wire rope hoist has several advantages over a mechanical hoist, the most important of which is its ability to lift much heavier weights than a motorized hoist. This makes them ideal for lifting large and heavy components like industrial machinery or construction equipment. Since they are much more efficient at lifting heavy loads than their mechanical counterparts, they are also much more cost-effective to operate.

Types of Electric Wire Rope Hoists

There are two different types of electric wire rope hoist that manufacturers use to meet different lifting requirements: A continuous-duty hoist, and a duty cycle hoist. A continuous-duty hoist is designed to operate continuously at full power, using a single electrical wire. A duty cycle hoist uses two or more electrical wires to operate at different power levels. Duty cycle hoists can be used for lifting more than one load at a time, with each load receiving its own set of controls. Both continuous-duty and duty cycle hoists are powered by electricity. Duty cycle hoists are often used in food manufacturing and in metal fabrication, while continuous-duty hoists are more common in general manufacturing.

Maintenance of Electric Wire Rope Hoists

Electrical wire rope hoists are maintenance-free and can be used with no lubrication. However, they tend to accumulate a bit of dust, so you should regularly vacuum them. You can also use a cloth to clean them. These hoists are also relatively easy to maintain and repair. Most manufacturers provide a maintenance schedule to help you keep them in good working condition.

Cost Savings of Using Electric Wire Rope Hoists

Lifting components with an electric wire rope hoist has many advantages over using a mechanical hoist. The most significant of these is the ability to lift much heavier weights than a motorized hoist. This makes them ideal for lifting large and heavy components like industrial machinery or construction equipment. Since they are much more efficient at lifting heavy loads than their mechanical counterparts, they are also much more cost-effective to operate.

Installation Tips for Electric Wire Rope Hoists

Installation of a wire rope hoist is relatively easy. However, you should always check the manufacturer’s instructions to make sure you follow their specific requirements for your specific installation. Here are a few general tips for installing an electric wire rope hoist: Use a mechanical hoist for installation. Never use electrical wiring as a guide for installing a hoist. Make sure that your power source meets the hoist’s requirements. Make sure that the hoist has enough clearance from surrounding objects. Make sure that the hoist is level and at the correct height for the work surface. If the work surface is uneven, you might need to adjust the hoist’s height to make it level with the work surface. Make sure that the hoist is installed where it will not be subject to traffic hazards. You might not want to install the hoist in a place that would interfere with the regular operation of the facility.

Wrapping Up

With all of these advantages, it’s no wonder that electric wire rope hoists are quickly becoming a favorite among manufacturers. Because they are maintenance-free, require little to no lubrication, and can be used to lift heavy loads, they are becoming a popular choice for production facilities that need to move heavy components. If you are looking to save time, increase efficiency, and lower costs, an electric wire rope hoist could be the perfect choice for your production environment. Now that you know more about these hoists, you can better decide if this type of equipment is right for your business. If you are ready to get started, you can check out our list of the best electric wire rope hoist manufacturers to find a hoist that is right for your needs.

Checkout Our Products: